In a small plastic tub mix 3 tbsp. Anodizing protects an 80 lower from the environment quite well.

Samples Of Type Ii Anodizing Dyes For Color Anodize Finish On Aluminum Anodising Color Chart Patina Color Chart

Samples Of Type Ii Anodizing Dyes For Color Anodize Finish On Aluminum Anodising Color Chart Patina Color Chart

This will be for type II anodizing type 2 anodizing.

Type 3 anodizing at home. After wading through the first paragraph or two I came across good information on the process. 2 Put it in an acidic electrolyte. Type-III thickness is defined as any thickness greater than 1mil 254 microns.

Type II is the conventional sulfuric acid anodize which can be decoratively dyed nearly any color and results in a thickness of 00002 00006. With the right tools and serious safety precautions you can anodize your raw 80 lower at home. The thickness of the anodising coat or 2 to 4 times that of normal type II anodising.

Type III - this is hard coat anodization or Hard Anodising. Hard clear anodizing Type III Class I may be processed without sealing. Type 3 Hard Anodizing -.

Surface Techniques utilizes a deionized waternickel acetate seal for our Type II and Type III color work. Hardcoat Anodize is Type III which is done under more exacting process conditions resulting in a. 44 ml of lye in 1 gallon 38 l of distilled water.

Type III anodized surfaces can typically only be dyed black or dark green due to the denser pore size. Through this process a film thickness of 0002 to 0004 can be achieved and that offers a surface coating with hardness characteristics second to diamonds. Most places that improperly say that their product is Hard Coat or Mil-Spec anodized only anodize only anodize to a thickness of 26 - 30 microns 101 - 12 mils.

Anodizing is an electro-chemical process. The operating temperature is controlled between 28-32º F but in some instances an acceptable oxide can be achieved at slightly higher temperatures. I know other people may to this step.

Anodizing SystemsType III anodizing is performed in a sulfuric acid bath containing 180-200 grams per Liter of acid and a small amount of dissolved aluminum. Type 3 is much harder to die because the pores in the anodised layer are much smaller than in Type II so the die finds it more difficult to penetrate. According to the Ron Newman anodizing page Type III hard coat anodizing is done at much colder temperatures and at higher current densities and can reach thicknesses of 002.

Dilute lye in water to create a scouring solution. Anodizing is what the majority of standard AR-15 80 lower receivers are finished with. The rectifier included in this system will anodize parts up to 4 sq feet at 6 amps per square foot.

It is a much thicker and harder coating than a standard anodize coating and is not usually dyed. Type I is chromic acid anodize or chromic alternatives which are very thin on the order of 00001 thick. Obtaining Type-III thickness at home is the easy part.

The other benefits of Type III anodizing services include. Hardcoat Type III Anodizing System. I do not cover the hard coat procedure because it is not in the home brew category due to the colder acid.

3 Run a DC voltage through it. Of course there is a little more involved. Heat Up the Dye.

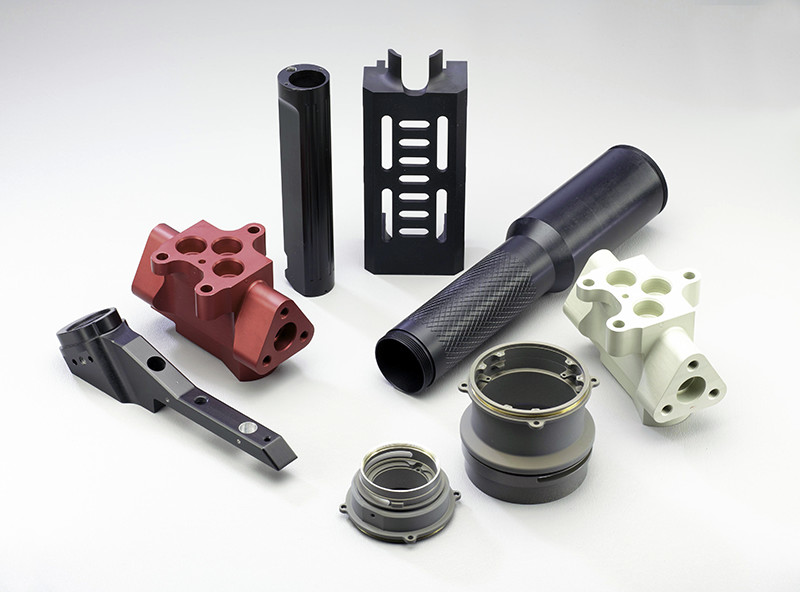

Hardcoat Type III aluminum anodizing is a coating frequently found on firearms and aircraft parts. F 10 percent vv sulphuric acid and a voltage probably somewhere between 48 and 75 volts. Type III aluminum anodizing also called hard coat anodizing or hard anodizing is used to increase the wear and corrosion resistance increase the surface hardness and improve the thermal and dialectical properties of treated aluminum objects.

Sealing Type III Class I adds a small increase in corrosion resistance but also give a small decrease in abrasive resistance. Get your Baths Ready. The anodizing voltage is also increased to 50-90 volts.

Allow it to sit for 3 minutes then. That is the type of anodizing that takes dye well and is typically used mainly for cosmetic purposes but also adds a hard aluminum oxide coating to the part that is very corrosion resistant as well as wear resistant and has electrical insulating properties. Make sure you have a solid electrical connection to part2.

Wearing a pair of rubber gloves place the object you want to anodize into the lye solution. Anodizing Your Raw 80 Lower. Coating Description Type III the temperature of the sulfuric acid must be reduced to 0 C 32 F.

Type III anodizing services are obtained by using an electrolyte of sulfuric acid at a low temperature in conjunction with a high voltage and current density. Ok for this step were going to set up a couple of baths. Hard Anodising or Type III anodising uses sulphuric acid again but a weaker solution.

You could dye them with a black dye to be slightly darker but they do not readily accept dye. Type III coatings will appear as a Dark Grey color. Link to the Anodizing calculator.

This allows the anodizing to build to a heavier thickness MIL-Standard. Type III coatings of 2 mils can be achieved by anodizing at 6 amps per square foot for 2 hours. There are proprietary additives that allow a type two and a half anodizing at higher temperature and somewhat lower voltage but true type III anodizing requires operating at about 28 deg.

It goes something like this. Anodizing parts in my garageI am an amazon affiliate and make profits from the links belowRed dyehttpsamznto2JoKYnhBlue dyehttpsamznto2Hvtsw5Hot. Standard dyed Type II anodize is generally around 075.

Turn off the power to the anodizing tank. Get out that tea kettle and warm up the dye checking the temperature with the meat thermometer. Aluminum anodizing is typically referred to by its three types.

Type 2 Type 3 Anodizing Services Type Iii Hard Coat Anodizing

Type 2 Type 3 Anodizing Services Type Iii Hard Coat Anodizing

Types Of Anodizing How To Anodize Episode 2 Youtube

Types Of Anodizing How To Anodize Episode 2 Youtube

Aluminum Anodizing Industrial Metal Finishing Anoplate Inc

Aluminum Anodizing Industrial Metal Finishing Anoplate Inc

Type 3 Hard Coat Anodizing Ams 2468 Incertec

Type 3 Hard Coat Anodizing Ams 2468 Incertec

Type 2 Type 3 Anodizing Services Type Iii Hard Coat Anodizing

Type 2 Type 3 Anodizing Services Type Iii Hard Coat Anodizing

Understanding And Specifying Anodizing Omw Corporation

Understanding And Specifying Anodizing Omw Corporation

Type 2 Type 3 Anodizing Services Type Iii Hard Coat Anodizing

Type 2 Type 3 Anodizing Services Type Iii Hard Coat Anodizing

Everything You Need To Know About Anodizing Aluminum 3erp

Everything You Need To Know About Anodizing Aluminum 3erp

Lcd Aluminum Anodizing Kits Standard Amp Deluxe Caswell Canada

Lcd Aluminum Anodizing Kits Standard Amp Deluxe Caswell Canada

What Is Hard Coat Anodizing Process Of Hard Coating Aluminium Aluminium Metal Anodized

What Is Hard Coat Anodizing Process Of Hard Coating Aluminium Aluminium Metal Anodized

Aluminum Anodizing Process And Design Guide Accurate Metal Finishing

Everything You Need To Know About Anodizing Aluminum 3erp

Everything You Need To Know About Anodizing Aluminum 3erp

Aluminum Anodizing Motorcycle Parts Metal Working Motorcycle Parts Anodized Aluminum

Aluminum Anodizing Motorcycle Parts Metal Working Motorcycle Parts Anodized Aluminum

Type 2 Titanium Anodizing Anodized Titanium Titanium Anodized

Type 2 Titanium Anodizing Anodized Titanium Titanium Anodized

Aluminum Hard Coat Anodize Type Iii Anodizing Mil A 8625

Aluminum Hard Coat Anodize Type Iii Anodizing Mil A 8625

Understanding And Specifying Anodizing Omw Corporation

Understanding And Specifying Anodizing Omw Corporation

Anodizing Process For Metal Parts In 2021 Metal Process Art Studio

Anodizing Process For Metal Parts In 2021 Metal Process Art Studio

Universal Type 4040 Aluminium T Profile Extrusion Aluminum Extrusion Extruded Aluminum Extrusion

Universal Type 4040 Aluminium T Profile Extrusion Aluminum Extrusion Extruded Aluminum Extrusion

0 Response to "Type 3 Anodizing At Home"

Posting Komentar